· Chris Hammond

Last Updated

1975 Triumph TR6 Alternator Upgrade and Replacement

A little documentation on some of the struggles I had with the alternator in my Dad's 1975 TR6

So now for a little story about the Triumph. The first of potentially many. Another Project car!

What Triumph?

What Triumph you might ask? My Dad purchased this car in 1985 when he was stationed at Seymour Johnson Air Force Base in North Carolina. He owned the car up until he passed away in September of 2023. My brother and I have both decided that the car won’t leave the family, so I’ve got it at home in my garage for now, at some point he will likely take it too.

So let’s get into some details. The Triumph has been in decent shape for its whole life, Dad used to spend hours working on it, seeing him do that got me doing the same on my 1973 Super Beetle back in the day. The last time I drove it, either late last year, or early this year, I was taking it from the house to my parent’s storage unit, wanting to get it out of our garage for the winter so that we could get some of our own vehicles in the garage, and at the time I also still had the Corvette in the garage.

On my way to the storage facility (one evening, so it was dark or getting dark), it started to act funny, run funny, kicking and choking. I managed to pull into a grocery store parking lot trying to determine what was going on, and ultimately pulled through that lot into a parking lot for the local Library. At that point it died and I couldn’t get it started. I called up a buddy who happened to live within a 1/4 mile of the library and he came over to help tow me to the storage lot, just another mile or so from the library. Before we tried towing it though we threw a little battery jump box that he had onto the car, that allowed me to start the car up and drive it the rest of the way to the storage lot, but as I pulled in to enter the keycode to open the gate, the car died again, draining the jump box.

We pushed it down to the storage room and put it away for the winter. I figured either the battery died, or the alternator died, so I would need to check those out and replace one or both come spring time.

Time to get the Triumph home

I started by getting back over to the storage unit and grabbing the battery out of the car. Took it home, charged it. Then took it to Autozone to have it tested. Battery tested okay. So that left me with the idea that the alternator must be shot. One afternoon I called my buddy who helped me get the car back to storage, he shuttled me to the storage unit and then followed me home as I drove it back home on the fully charged battery. No issues getting home running on just the battery, but it was done during the day so the headlights weren’t on.

With the car home I decided it was time to order an alternator, first looking at Moss Motor’s website to see what they had in terms of an Alternator for a 1975 Triumph TR6. They had a rebuilt unit, available for cars with an air pump, for $450, quite pricey (I didn’t realize at the time that included the refundable $200 core charge). I thought there might be a better option so I searched around, initially at local autoparts stores and online, but I simply couldn’t find an alternator that would work. After searching for a bit I started stumbling on some threads in old british car forums suggesting that you could swap out a 75 alternator with one off of a 78-80 Ford Fiesta.

From reading, it appeared that it should simply be a drop in replacement without modification to wiring, so I figured I would go that route, a benefit of the change would be improved amperage of the Fiesta alternator as well. I ordered a unit from RockAuto, part number 13107N. Upon receipt I realized it wouldn’t quite be as drop in friendly as I had hoped. When I tried to mount it to the side of the engine I realized that the holes wouldn’t align to allow me to mount it and use the tensioner that was used on the previous Lucas alternator.

Getting Help for the Triumph Alternator

Reaching out to Dave at Solo Performance Specialties for some advice (he’s my go to for all advice) I learned that you can “clock” an alternator, which basically involves taking the shell apart and rotating it to get the right location for mounting into the car.

Clocking an alternator seemed pretty straightforward, undo three sets of nuts and bolts, remove the cover, rotate the cover (120 degrees so that the flange lines up) to the right position, and then put it back together. And it went just as simple as that. I had it apart and back together in under 15 minutes, but as I was done and getting up from where I had been working on the alternator I came across a small piece of what looked like a magnet on the floor. I thought “oh damn, I broke something”. So I took the alternator back part and started looking for broken bits inside to see if I broke something. After looking it over, it sure looked like things were in their appropriate location, so I put the alternator back together and got to putting it back into the car.

Upon putting the alternator back in the car I figured out my next problem. With clocking it, the hole in the flange where the bolt would go through was no longer big enough for the previously used mounting bolt. That was an easy fix though, I grabbed a 5/16” drill bit and a hand drill and opened it up a bit to make everything fit. From there it was a matter of plugging in the wires, putting the belt on the pulley and starting up the car.

Ignition bulb powers alternator?

Oh I forgot to mention, while I was looking around for info about clocking the alternator I came across some forum threads that talked about an Ignition light/lamp on the dash of the TR6 that should light up when you turn the key on, and go out when the car is running and the alternator has engaged and is charging. I also read that if the bulb in that lamp goes out, the alternator won’t charge the battery. What? Yeah, you read that right. If the ignition light bulb on a Triumph TR6 is burnt out, the alternator will not work and charge the battery.

So this led me down the path of trying to see if that bulb worked. When I turned the key on, it didn’t appear to light up, so I reached up into the dash to see if I could access it, it easily came out of the back of the dash. Basically the whole socket pulled out, easily removable from within the gauge cluster. I pulled the bulb out and took it with me to a parts store. I tried Napa, the guy there figured out the part number, but unfortunately didn’t have a replacement bulb in stock, part number 1449. I drove 30 minutes to a Carquest whose inventory showed in stock online, only to be told they couldn’t find them. A quick search on Amazon and order placed would get me a new bulb the following day.

Sunady morning I waited around for the delivery of the bulbs from Amazon, upon receipt I put it into the sock and turn the key on, no dice, the bulb won’t turn on. I look at the box and realize I actually ordered bulb 1446, not 1449. Another Amazon order placed and a few days later I had the proper 1449 bulbs in hand.

Once again, put the bulb in the socket, turn the key, and nothing. WTF. Long story short, apparently the bulb isn’t grounded, and won’t light up just hanging below the dash. I eventually put it back into the gauge cluster and turned the key, and what do you know, the ignition light came on.

Now on to starting the car and seeing if the alternator worked. Nope…

The bulb would turn on, the car would start, but the bulb would never go out. As I understand it, the way the alternator works is it needs a 12v signal to “start” up, while the belts running and it receives that signal, once it is up and charging, it grounds that signal and the ignition light goes out. (I’m not an electrician, if any of that is wrong, apologies) No matter what I tried, I couldn’t get the bulb to go out, and I couldn’t get the battery to charge from the alternator. I started testing out the voltage at the battery, on the back of the alternator, elsewhere, and nothing showed me any juice coming form the alternator more than the battery voltage, this told me that the alternator wasn’t sending power to the battery and thus wasn’t charging.

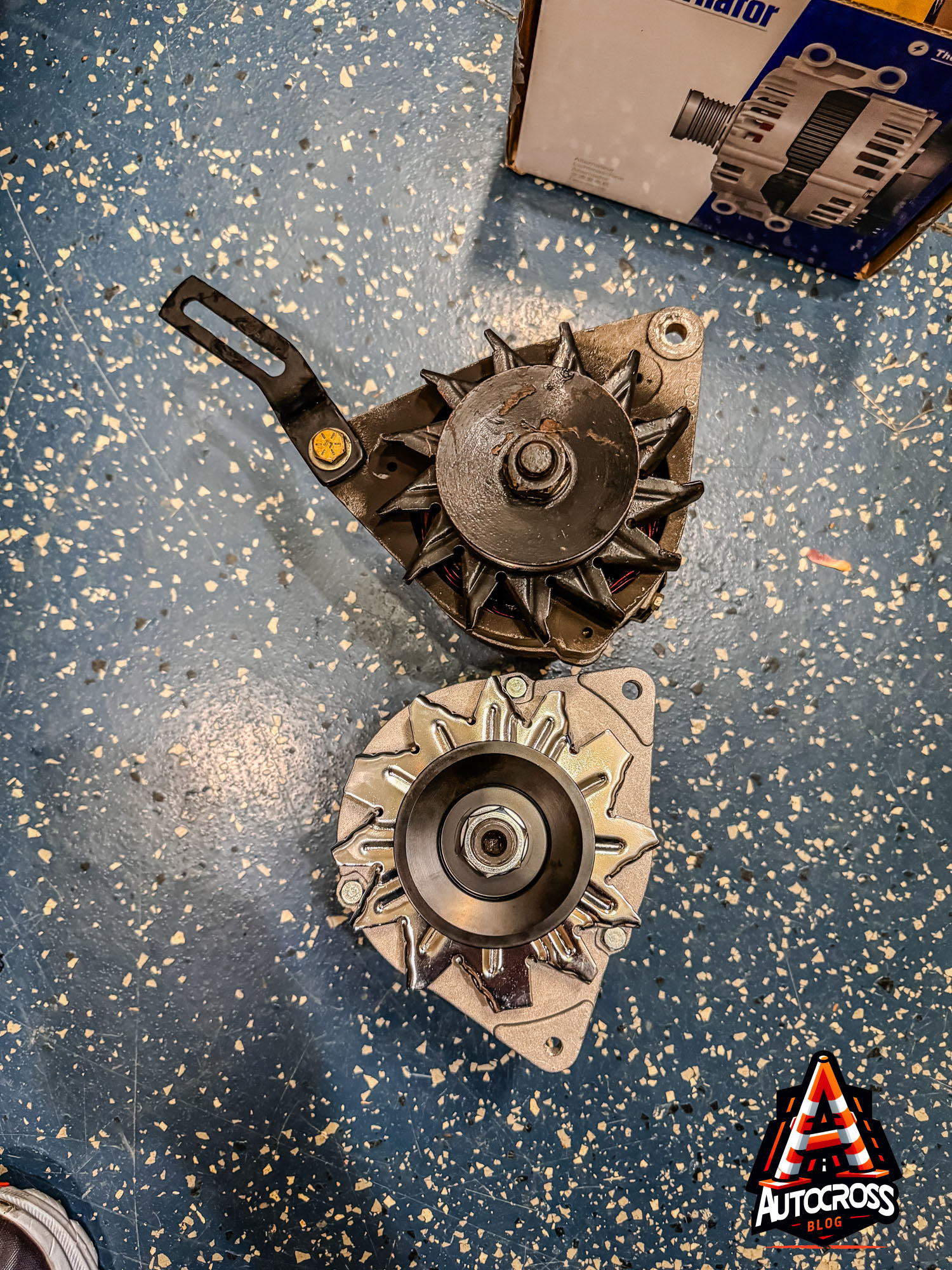

Getting the Alternators tested

I ended up taking the original Lucas alternator (FYI, I don’t think it’s the original 1975 alternator, but likely one my father had put in at some point), to Autozone to get tested. The guy running the testing bench struggled quite a bit and never couldn’t quite get the machine working 100%, but at one point it did flash a “failed” message on the screen before quickly going off to some other screen that said it needed something else done. A couple of days later I brought the “New” alternator in as well, to see what it would test at. As I walked in the guy behind the counter (a different guy) asked “Didn’t you just bring that in the other day to test?”, to which I replied yes and no. This was a different alternator. He ended up getting it setup on the bench and testing it out. Sure enough, it also failed. On the autozone testing bench it was not showing as good, and thus not producing power. At this point he basically promised me he could get me an alternator, so I said go for it, I checked and your website said you couldn’t. A few minutes later he was defeated and I was on my way home, needing another alternator.

Ordering a second alternator

So off to RockAuto I went, ordering ANOTHER 13107N alternator for a 78-80 Ford Fiesta. I think I ordered it on Friday, had a predicted delivery date of Monday, but was delivered Sunday morning. After washing and cleaning one of the cars Sunday morning I got to work on the Triumph again.

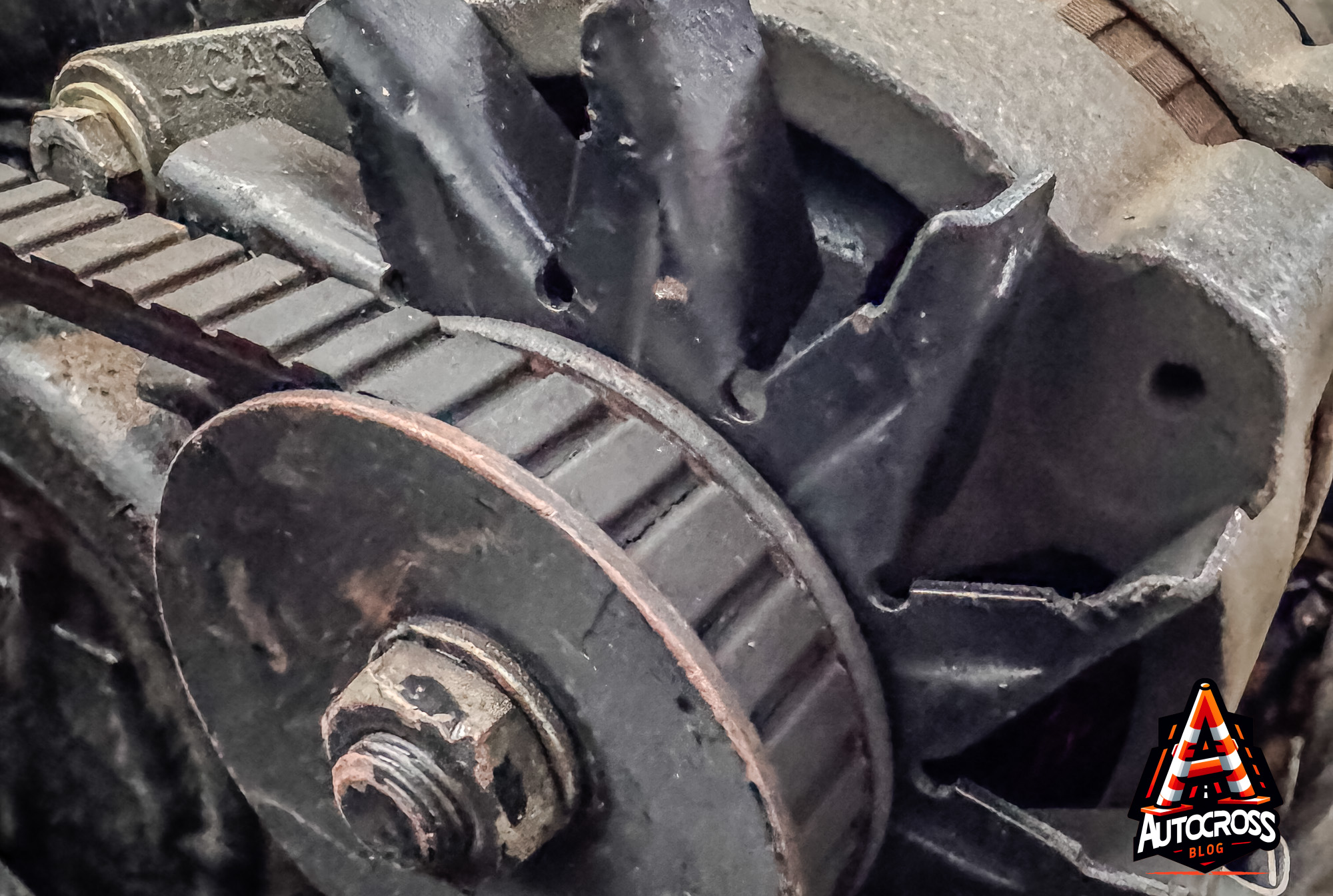

I seriously considered taking the new alternator to Autozone to test it out BEFORE I did anything to it, but went ahead and began the process of clocking it. This time however, things went differently. When I pulled it apart I immediately noticed two pieces down inside that stuck out and ultimately blocked the shaft of the alternator from being reinserted. They looked awfully familiar, just like the broken piece of randomness I found after clocking the other new alternator. What I figured out was that I had apparently broken those bits off in the first new alternator, though I only found one piece, not two from that one.

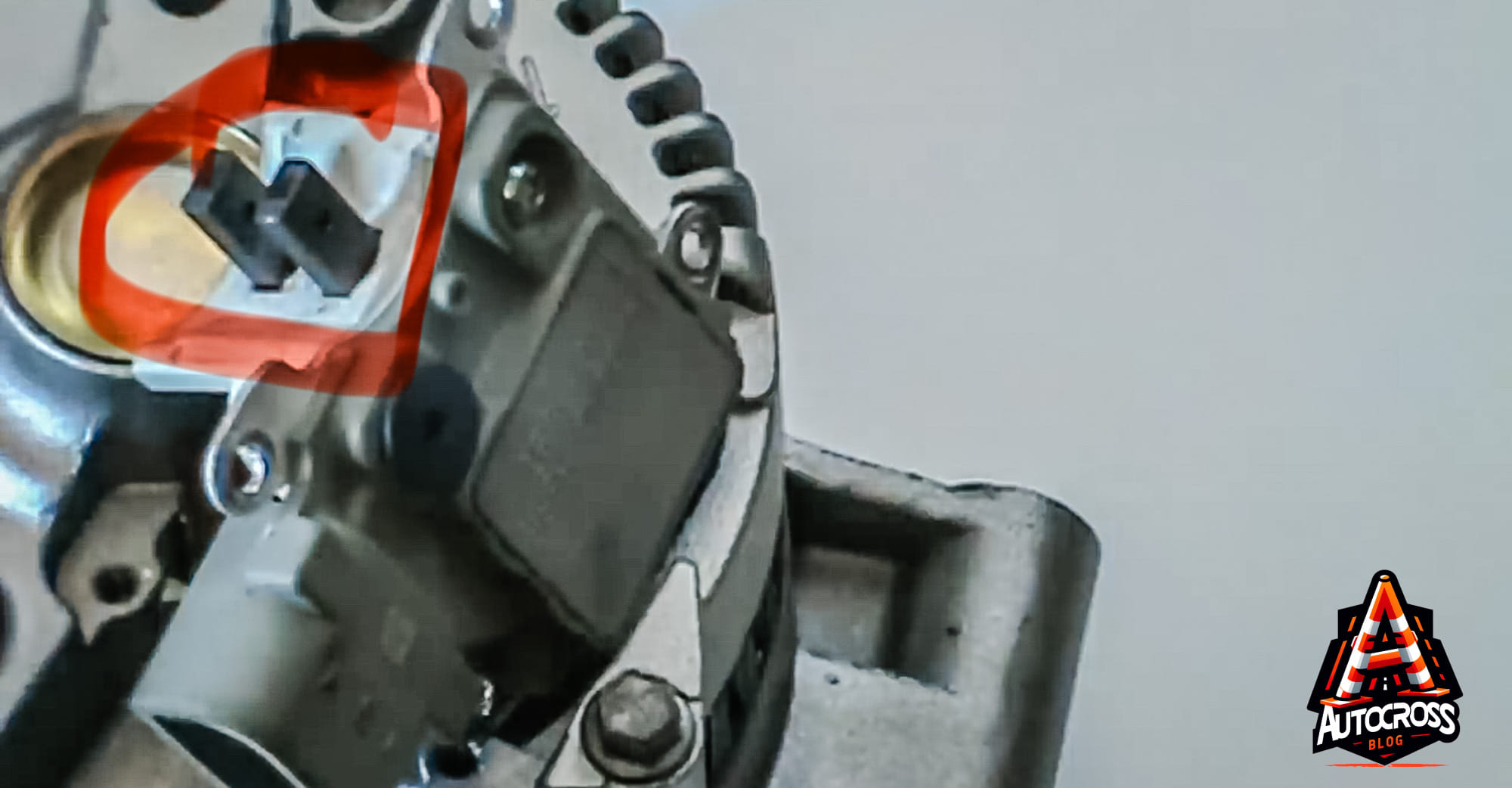

Anyways, this time around I made sure not to break those off, I think they are brushes, they ultimately are part of the voltage regulator and press up against part of the copper shaft when the alternator is spinning. I ended up having to take the voltage regulator off the back of the case, tie a string around those two spring loaded brushes to push them back into their position and hold them in place. I then reinserted the voltage regulator, finished clocking the body and then cut/removed the string. This allowed the brushes so go back in place.

From there the process was really straightforward, reinstall the alternator, plug things in and see how it went.

Success

As soon as I put the new alternator in, hooked up the wires and the belt, I started the car. The ignition light was on, and then fairly quickly went off. A quick check of the back of the alternator with a multimeter also showed a higher voltage coming from the alternator than the battery was sending!

A couple of last items for anyone who stumbles on this post when working on their 1975 Triumph TR6 alternator. The alternator actually has 3 wires, though you’ll see above in the pictures that I only have two hooked up, and I only had 2 hooked up on the lucas alternator that I pulled out. The third wire is another 12V, I believe that third wire was used on the OEM alternator, but on newer units it isn’t required. The wire was just sitting free in the engine bay as seen in the photo below. I will tie it off to keep it safely not connected to anything.

Extra alternators?

So now I have a couple of alternators sitting around the garage. I figure if I can order a new voltage regulator I can repair the 13107N that hasn’t been used. I’ll also hold on to the Lucas unit in case I need to CORE that at some point.

Now that the car is running again I need to get it inspected so I can get plates on it and drive it around town!